Repairing my mug with kintsugi

My coffee mug broke earlier this year. Naturally, you wouldn't be

reading this if it weren't avery special mug: It has accompanied me

every day for the last 10 years. Through my student days, startup days,

and early career, it has sat by my side with its goofy crocodile decals

and brightened my desk. We've shared several thousand cups of coffee. That

was until early February 2024. In a moment of inattentiveness, I knocked

it off the kitchen counter and, giving into the idiotic reflex of trying

to catch it with my foot, kicked it into the wall instead. I can still

hear the sound of it shattering...

After recovering from the initial shock and collecting the sad remains

of my mug, several colleagues offered their condolences and suggested I

look into the ancient Japanese art of Kintsugi. I did, and four months

later, my coffee mug is back in action! I wanted to write this post to

share what I learned along the way.

Discussed on Hacker News.

The art of Kintsugi (Japanese: 金継ぎ)

Kintsugi is the traditional Japanese art of repairing broken pottery.

In Kintsugi, one uses natural lacquer mixed with various ingredients such

as wood powder, polishing compound, and even bread dough to repair cracked

pottery. The mended joints are then highlighted by dusting the final layer

of lacquer with gold or silver. We Westerners might find this last step

peculiar: why would you highlight a repair? In fact, why bother repairing

a broken mug at all? Shouldn't a broken thing either be discarded and

replaced, or repaired to look as good as new? According to traditional

Japanese philosophy, however, an object's imperfections are to be celebrated. They tell

the story of the object’s history.

With the shards of my beloved mug safely stowed away, I started reading

about Kintsugi and how one might go about practicing it at home. These

days, some hobbyists opt for modern epoxy instead of the traditional and

expensive Urushi lacquer. Epoxy probably yields a more robust bond and

certainly allows for quicker repairs, but I question its safety for

food-related use, especially at the temperatures found in a steaming cup

of coffee. Also, the idea of using epoxy didn't feel right to me—I

wanted to do this the proper way or not at all. That meant investing

many yen to obtain what is widely regarded as the best

Kintsugi starter kit made by the folks at TSUGU TSUGU. While waiting

for overseas shipping, I familiarized myself with the process by

watching their tutorial

over and over again.

Step 1: gluing the pieces together with mugi urushi

When your pottery has shattered into different pieces, the first step

is naturally to glue them together again. Before gluing, the pieces need

to be thoroughly cleaned and any sharp edges smoothed so that the seams

become more pronounced. This aids the later steps in the process.

Already here I encountered my first hurdle. The guides I was following

worked with clay pottery, while my coffee mug is glazed ceramic. In case

you didn't know, ceramics are surprisingly resilient; sanding it isn't

easy. I had coarse 200-grit sandpaper at hand, but a diamond file would

most likely have been a much better tool for this job.

Mistake 1: Sandpaper doesn't work on glazed ceramics.

Use a proper diamond file.

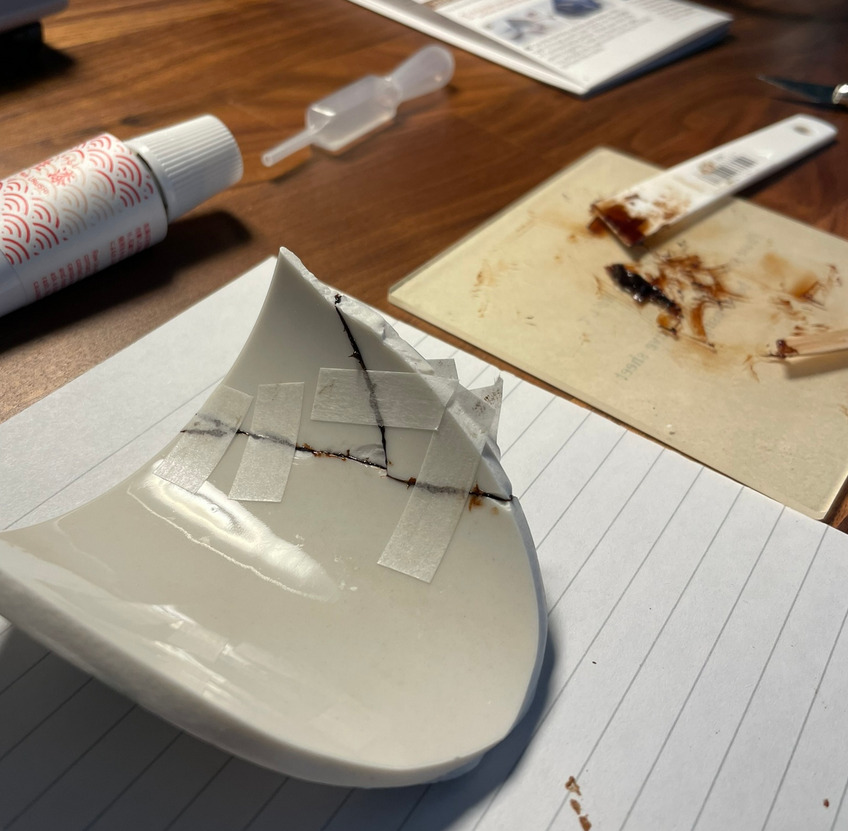

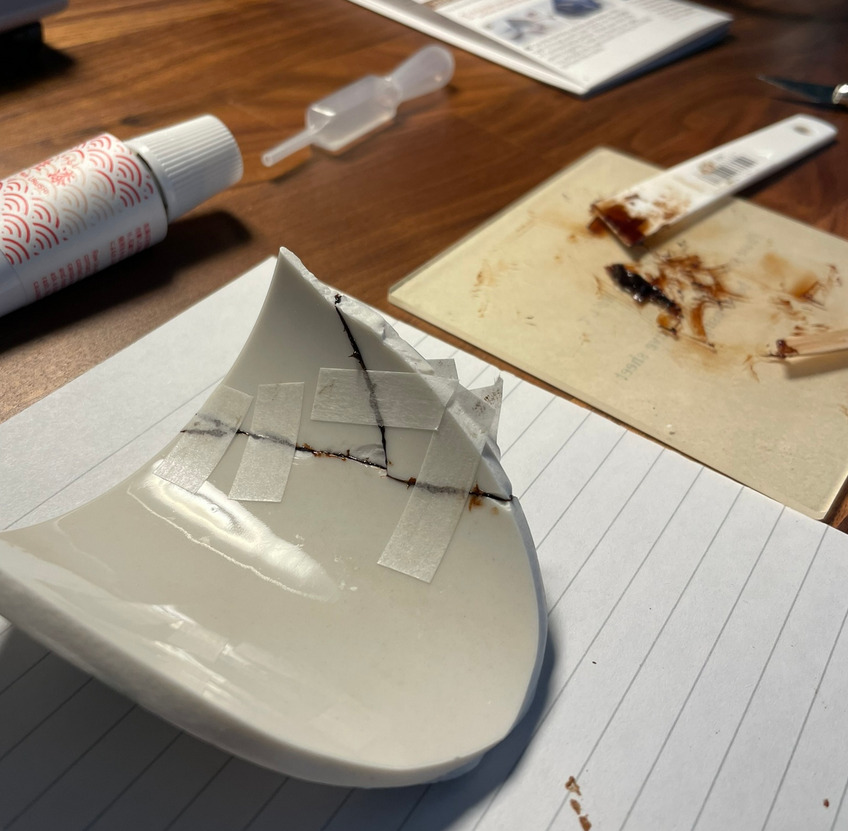

After smoothing the edges, it's wise to test-fit the pieces together: I

rebuilt the cup from its fragments using some masking tape. This allowed

me to get a feel for how they fit together, which pieces I was missing

(luckily not many), and which pieces were too small to handle. You can

rebuild a surprising amount of the object's structure with kintsugi

techniques, so leaving small shards out of the repair is not a big

problem.

All the pastes, glues, and lacquer products used by kintsugi artisans

are based on the resin obtained from the Urushi tree. Urushi lacquer

contains urushiol, an organic compound named after the tree from

which it is harvested. Incidentally, urushiol is also what makes poison

ivy... poisonous. Most humans are allergic to this compound. Gloves are

definitely recommended when working with urushi resin.

Urushiol hardens to form a very hard and scratch-resistant lacquer under

the right conditions: around 25°C and 75% relative humidity. These

conditions can be simulated by placing a wet towel in a cardboard box

and leaving it in a warm place. I managed to convince my fiancé that

this cardboard box just had to live in the bathroom cupboard and that

the hairdryer now lives elsewhere and yes this is super critical because

it's my passion project right now. I kept tabs on the environment of my

urushi box using the

world's best CO2 sensor (full

disclaimer: I work at Disruptive Technologies) to make sure I was

alerted when the conditions deviated too much from my target.

The glue used to stick broken pieces together in kintsugi is called

mugi urushi. Strangely, it's made by first mixing cake flour with

water and forming a small ball of dough. I suspect the gluten in the

dough helps achieve the right consistency. The dough is then mixed with

small amounts of raw urushi until it reaches the consistency of freshly

chewed gum. At least, that's what the kintsugi guide told me. I was

surprised when I suddenly had something indistinguishable from brown

slimy chewing gum and hoped I was on the right track.

Using a suited poking implement (the kit came with a well-shaped bamboo

stick), I smeared the sticky glue onto the edges of some of the larger

shards and pressed them together. Mugi urushi is sticky enough that

pieces will hold together fairly well, making it easy to fasten them

properly using small pieces of masking tape. The guide recommends not

gluing more than a few pieces together at once and to focus on larger

pieces to begin with. Following this advice, I planned to glue my mug

together in two sessions.

Once glued and taped, the broken pieces were placed into the humid and

warm cardboard box for around 2 weeks. At this point, the glue had

hardened to the point where scraping at the squeezeout with a razor

blade caused it to chip and flake off. If the glue feels gummy, leave it

in the urushi box for another week -- it will harden eventually. If it

doesn't, the mugi urushi might have been contaminated with oil and you

will have to start over. Dissolve the mugi urushi with acetone and

restart. I luckily did not encounter this particular problem, but that's

what Reddit recommends.

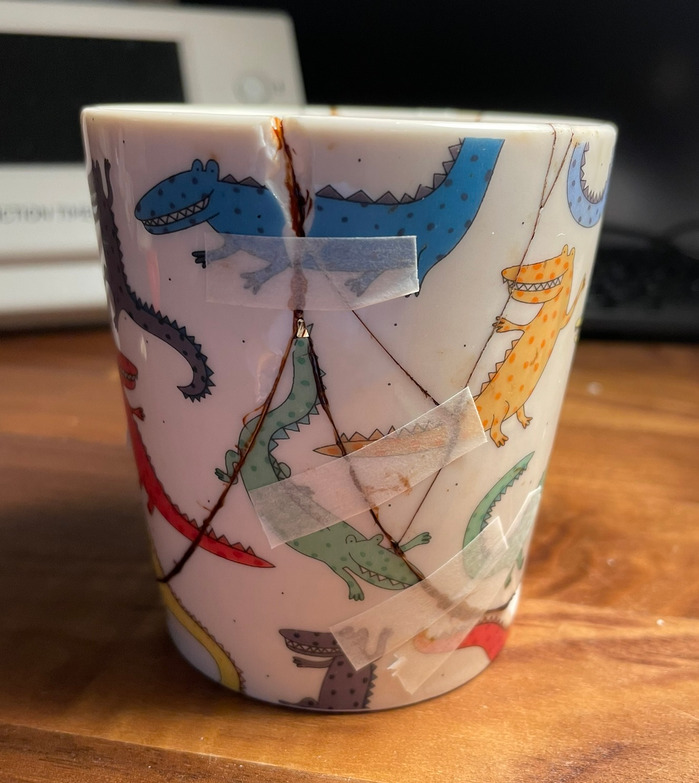

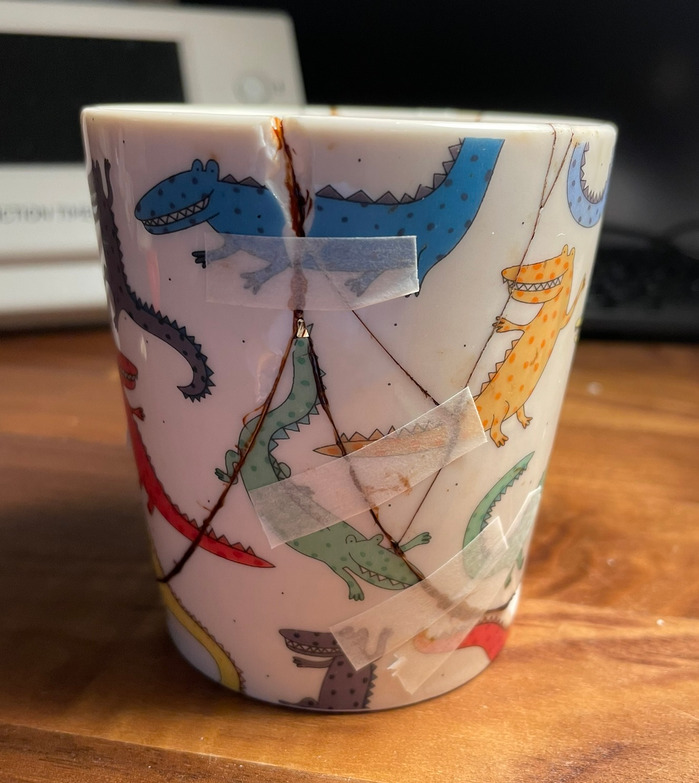

The 2nd round did not go as well. I quickly realized that my first

glue-up was slightly crooked.

Mistake 2: Even the smallest misalignment will haunt

subsequent glue-ups. Take care and plan well.

I did not test-fit the first glue-up with the other pieces before

letting it harden because I was afraid to smear the squeezeout and

smudge the ceramic surface. I now realize that this wouldn't have been a

problem, because you can easily sand away any smearing on glazed items.

For raw unglazed (rough) pottery, this is probably not the case though.

In any case, the 2nd glue-up did not go very well because of the

misalignment with the first. In hindsight, I should have started over at

this point, but oh well.

Cleaned and sanded pieces

Gluing with mugi urushi

2nd round of gluing

Urushi hardens in a warm and humid box

Step 2: filling gaps with kokuso and sabi urushi

After gluing the broken pieces together, it's time to start rebuilding any

missing structure. It's hopefully evident from the photos that I'm missing

a fairly large chunk near the bottom of the mug as well as a couple of

fragments near the lip. There's even a hole straight through the ceramic!

You can also see the misalignment resulting from my haphazard glue-up in

that the rim of the cup isn't flat. A true kintsugi artist would never let

such a blemish fly. Luckily, I can go full meta and say that the

misalignment tells a story of my kintsugi journey, and the mug will be

that much more valuable for it. After all, that's the spirit of this whole

project!

Luckily, there's a process for dealing with (and celebrating) defects like

holes and missing pieces. Large holes deeper than 1 mm are filled with

kokuso. Kokuso is made by taking mugi urushi (the gum glue used

earlier) and mixing it with equal quantities of wood dust and polishing

compound. At this point I simply trust the process—I couldn't begin to

tell you why these particular compounds are used.

Once mixed, kokuso has the consistency and appearance of hard clay. I

worked kokuso into the cracks and holes in 0.5 mm layers. Kokuso can be

flattened by covering it with plastic clingfilm and pressing on it with

your finger. Between each layer, kokuso is allowed to harden for one week.

Once cured, it is sanded flush with the contours of the surrounding

geometry.

I needed two layers of kokuso to rebuild most of the structure, and the

2nd layer took several weeks to fully cure. I believe this is because I

did not clean my tools well enough. The kintsugi guide recommends cleaning

all tools with mineral oil between sessions precisely because oils will

prevent urushi from curing, and I suspect I did not do a proper job of

cleaning the oil off my spatula when making the 2nd round of kokuso.

Mistake 3: Even the smallest amount of oil will

significantly prolong cure time.

Small holes and cracks shallower than 1 mm are filled in using sabi

urushi. This is made by mixing polishing compound with water, little

by little, until it reaches the consistency of hard mayonnaise. To this,

you add raw urushi (around 60% by volume). The guide says that sabi

urushi hardens "quickly" and boy is that an understatement. In

less than 10 minutes, my sabi urushi was hard and useless. I had to

practice making sabi urushi a couple of times until I had the process

nailed before I even had time to apply it to my cracks. Unsurprisingly,

I found the ticking sabi urushi clock to be very stressful, so I will

admit that I did not spend enough time on this part of the process.

Mistake 4: Not spending enough time on the sabi urushi

process.

Had I done my job properly, I would have sanded down the hardened sabi

urushi and added several layers before moving on to the next part of the

process. I did not, and proceeded with several small holes and gaps in

my seams. These were not deep enough that I feared my mug would leak, of

course, but it's still a visual blemish.

These holes need filling...

A large shard is also missing

Kokuso is used to fill large voids

Sabi urushi fills smaller cracks

Step 3: applying black lacquer

The next step of the process is where the detail work begins. At this

point, the gaps are all filled, the cracks are smoothed over, and we are

ready to start working on the final surface finish. That's done by

repeatedly painting layers of

black urushi lacquer on top of every

part of our repair.

Black urushi is made by stirring a blob of raw urushi lacquer until it has

evaporated much of its water content. During this process, it transitions

from a dull beige color to deep wine red. To this, we can add black mica

powder to color it jet black. I don't think its color matters much at this

stage in the process. Using a fine tip paintbrush, I carefully painted the

lacquer on top of the sabi urushi. To my surprise, this was the most

difficult part of the whole process, especially painting the inside of the

mug. Save for painting houses, I have never used a paintbrush in this

capacity, nor do I have any drawing skills.

Mistake 5: Never learning to hold and use a fine-tipped

paintbrush.

Sure, I can trace a line with a ballpoint pen, but pens work in two

dimensions. Paintbrushes work in at least three: pressure widens the

brush and curves cause it to splay. Stray hairs muddle your line and you

must always be mindful of the amount of lacquer (or paint) your brush is

loaded with. I found it near impossible to paint nothing but the thin

lines of sabi urushi. This is without a doubt the part of the process

that I underestimated the most. I have gained an enormous amount of

respect for artists who paint for a living.

I laid down several layers of black urushi, making sure to cure each

layer for a couple of days and wet-sanding it smooth, to give myself

some practice with the frightfully difficult paintbrush. I noticed that

the black urushi tended to break off in flakes where I had painted

directly on the ceramic glaze rather than on the thin strip of sabi

urushi that makes up my seams. Apparently, urushi lacquer doesn't bond

very well to the glaze, and I believe I should have either (a) broken

the edges of the ceramic more thoroughly prior to gluing to widen the

seam or (b) pre-sanded the glaze along the seams.

Mistake 6: Not providing a scored base for the black

urushi to bond with the ceramic.

Black urushi is made...

...and applied with a paintbrush. Matte areas

are have been sanded.

Step 4: gold dust on bengal red urushi

This is the finish line! Several months of mixing exotic compounds

together, painting, brushing, sanding, and a

lot of waiting for

urushi to cure have led up to this moment. The final layer of lacquer is

applied at this stage. I'm going for a gold finish on my mug, and the

recommended base layer for this is

bengal red urushi. Painting or

sprinkling gold on top of red or earthy materials is apparently an old

trick to improving the overall color of the final result.

Bengal red urushi is made in exactly the same way as black urushi lacquer,

but uses red mica powder instead of black. The process of painting it is

also the same—i.e. frightfully difficult, even more so because this is the

final layer and there is

nowhere to hide your mistakes. No

pressure, hope you have steady hands.

After painting the bengal red base layer, you want to let it sit for a

while: it must be tacky but not liquid. 15-30 minutes, ish. Yeah, this was

also a point of worry for me. Experienced kintsugi artisans can probably

glance at the bengal red and know that it needs a few more minutes before

it is ready for gilding. I don't, I only have data: I spent 15 minutes

laying down the bengal red base coat, I waited exactly 30 minutes after

the last brush stroke before applying the gold powder. The room I worked

in was at 25.3°C with a relative humidity of 71.3% and the CO

2

levels hovered around 480 ppm. There was a full moon and a thunderstorm,

in case you wondered. After 30 minutes, the bengal red urushi was just a

tad too liquid when I started applying the gold powder.

Mistake 7: Not waiting long enough before applying gold

powder and smearing the lacquer.

A significant driver of the cost of the kintsugi kit I purchased was the

small amount of astonishingly fine gold powder that came with it.

Included were also a couple of balls of pure silk (because why not)

that, when coerced into small balls, will hold a small amount of gold

powder. Carefully, I brushed the gold-laden silk balls across the lines

of bengal red urushi and watched as they transformed, in the blink of an

eye, from earthy red to brilliant gold, as if by magic. That is, until I

applied a bit too much pressure and smeared some of the lacquer and made

a mess of a couple of parts of the seams. All in all, though, I believe

this part went okay. Far better than I feared, at least.

Bengal red urushi is applied before gold

powder

Goldfinger!

Final results

After a couple days in the urushi box, this is what I was greeted with.

It's not perfect by any stretch of the imagination, but I'm glad I had the

opportunity to dip my toes in the art of kintsugi. I'm also very excited

to finally have my mug back.