For the past few months (feb. 2016) and over around 200 hours I have been designing and building a

nixie-based alarm clock. The inspiration came from

those wake-up light clocks that slowly brighten a powerful light source before waking you up in

order to trick the brain

into thinking it's morning. That was early September 2015, and I think it's safe to say that the

project escalated quite a

bit. When I miraculously salvaged four

Amperex ZM1000 nixie tubes in November from a dumpster and managed to

bring them to life on a breadboard, I decided to really go all-in on this project. This has been the

first large-scale

project I have done in electronics, and will surely not be my last.

The clock now features an 8 digit, 7 segment display and a rather expansive menu system, allowing

the user to change just

about any thinkable parameter in the system. Interaction with the menu system is done with a rather

lovely 12 step rotary encoder, and

arming the clock is done by an arm switch and key. The transparent plexi glass front allows insight

into the guts of the system.

I will present each subsystem of the clock in the order of which they were designed and implemented,

thus giving the reader

a feel for the design process. Feel free to use any idea, code, schematic

or board layout, but remember to reference this website or myself if you do.

About the nixie clock project

The 7 segment display: hardware and software

I decided to start off by designing the 7 segment display, imagining it would come in handy for

debugging.

Being a fan of everything retro, I fell in love with

the Bubble Display from

Sparkfun. These were normally

seen in calculators and such back in the day, and are nothing short of awesome. While waiting for

those to arrive,

I set about designing the support circuitry for the 2x4 segments. This particular display is

common

cathode, meaning that every segment in the digits has common ground. There being eight

digits, I eventually

decided to use two

HC74595 shift registers to

drive the anodes and one TPIC6B595

shift register to sink the current from each cathode. I could have used one single shift register

for all the anodes,

but that would result in a 1/8th duty cycle, which looked a bit dim during breadboard

tests.

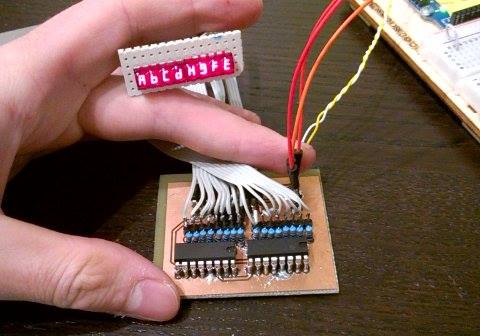

I was planning to use the laser print method

to create the PCB. Despite designing a two layer board, I struggled to organize all the connections

in order to keep

the shift registers and the displays on the same board and still keep the module's size reasonably

small. I therefore decided

to re-organize the connections with ribbon cables from the shift register PCB to a perfboard onto

which the display was soldered.

This solution became problematic when the whole system was being assembled, since a thick bulk of

ribbon cables is rather

unwieldy. Read the paragraph on Physical assembly to see how I turned that problem to my

advantage. You can find a download

link for the EAGLE files at the bottom of the page.

This is how I ended up multiplexing the display:

Despite a mere 25 % duty cycle and below-recommended segment current, the display is more than bright enough.

The screen assembly - before I noticed I had rotated the cathode wires on the right-most array.

Initial testing of common anode 7 segment displays. It's amazing how many jumper cables it takes!

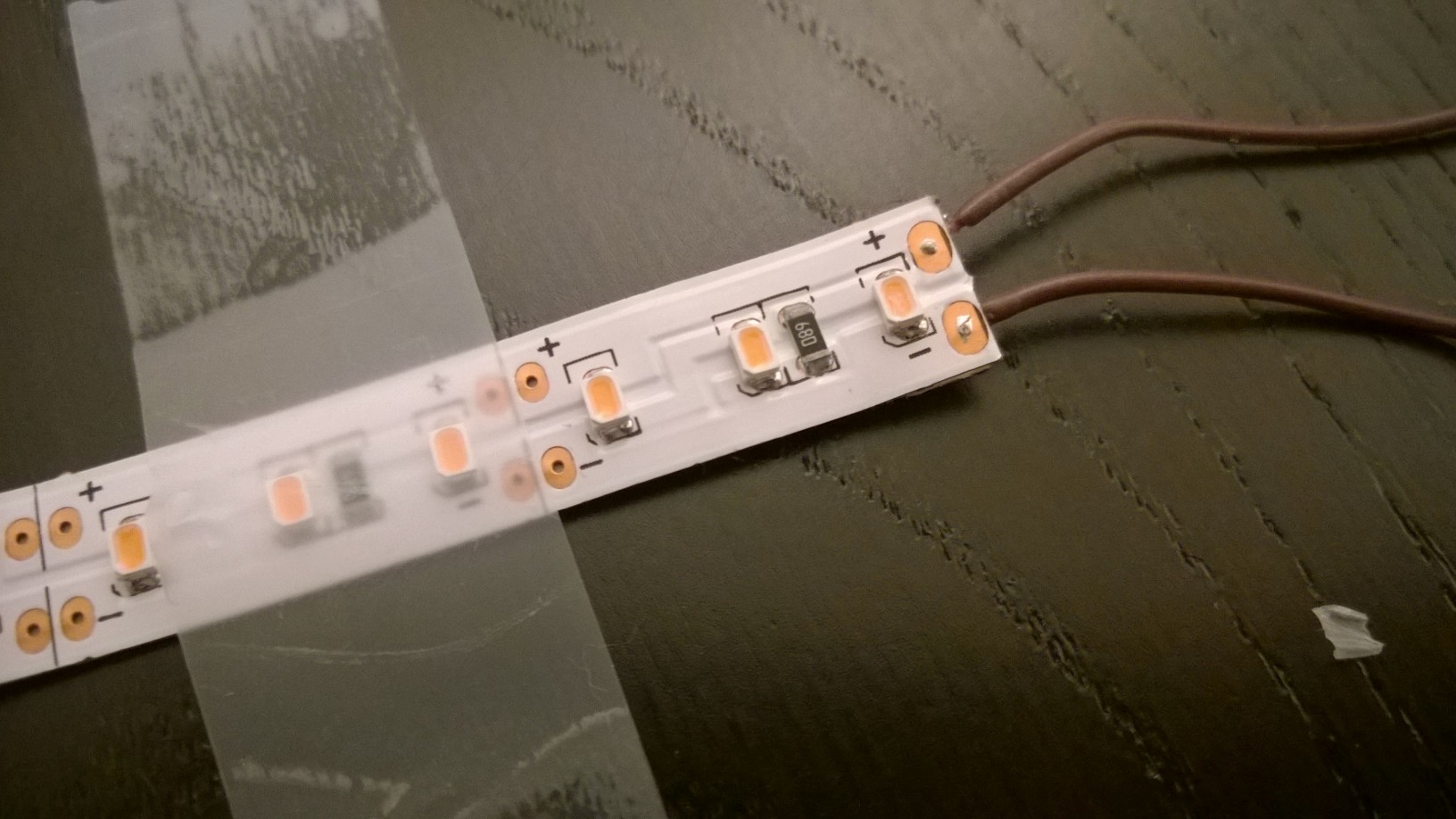

A 400 lm, 5 W, >93 CRI LED strip!

After reading up a bit on wake-up lights and following a never-ending trail of Wikipedia articles regarding sleep, hormones, light, color rendition indeces, sunlight and how humans perceive light, I realized why those commercially available wake-up lights are so expensive. From what I could gather it seems that the effect is strongly dependent upon the quality of light, which can be quantized as the light source's Color Rendition Index (CRI). CRI is a number which in essence tells you how well a particular light-source is at revealing an objects true color in comparison to a natural or ideal light source (often referenced to sunlight). Basically: High CRI = good light. The idea behind the wake-up lights is to trick your brain that morning is coming by simulating a sunrise, and is backed by research:

Dawn simulation units mimic the gradual twilight transitions found outdoors during spring and summer. These light signals are presented to people while they are still asleep, and while their eyes are still adapted to the dark of the night. This is the point where the circadian system is most susceptible to the phase advances of gradually brightening light. The presentation of diffuse, broad-field illumination evokes an antidepressant response and helps those affected by seasonal sleep disorders to wake up normally.

Terman, M., & Terman, J.S., 2005

I decided to use

FlexFireLEDs's ultrabright series LED strip

for this project. They are indeed rather expensive, but in turn they have a guarateed CRI of 93+, a

market

best as far as I can tell. They are also very bright at around 450 lm / 5W per foot. By

comparison,

a standard 40 W incandescent bulb is 450 lm omnidirectional. I can't look directly into the

lights

at full brightness without discomfort.

These LED strips run at 12 V, so by this stage in the project I had decided to use a standard 12 V

power brick

to drive the system. Driving them is easy; A simple, generic power MOSFET connected to an 8 bit PWM

pin on the microcontroller

enabled me to dim the lights.

The LED strip running at around 5 % duty cycle. It's painful to look directly into the light at 100 %! Notice how the first three LED's are dead...

I could not for the life of me get the solder to reflow on the top of the pads, so I soldered from underneath. The heat was probably set too high, so the first row of three LED's died. This is not noticeable though -- see the section on Physical assembly.

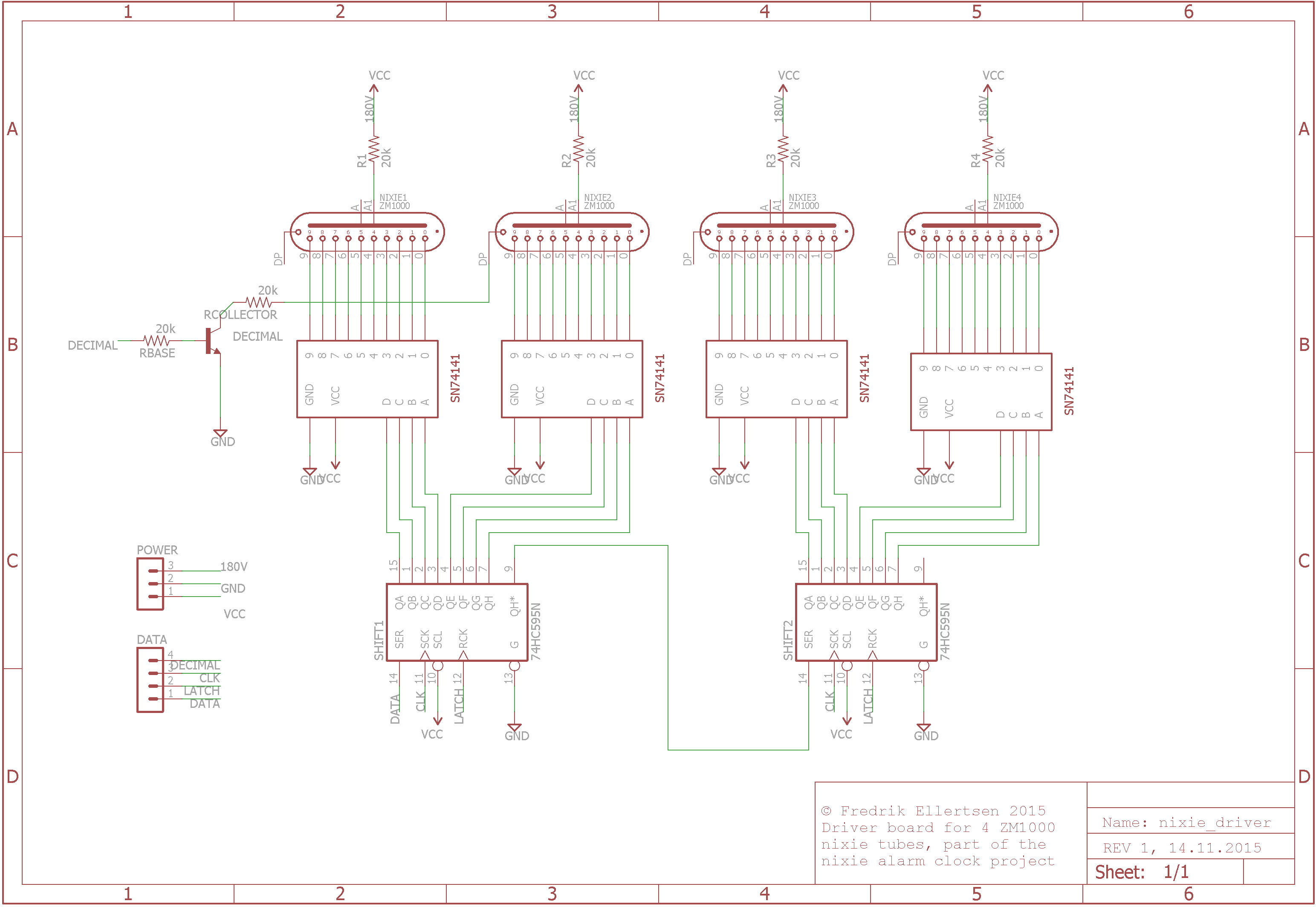

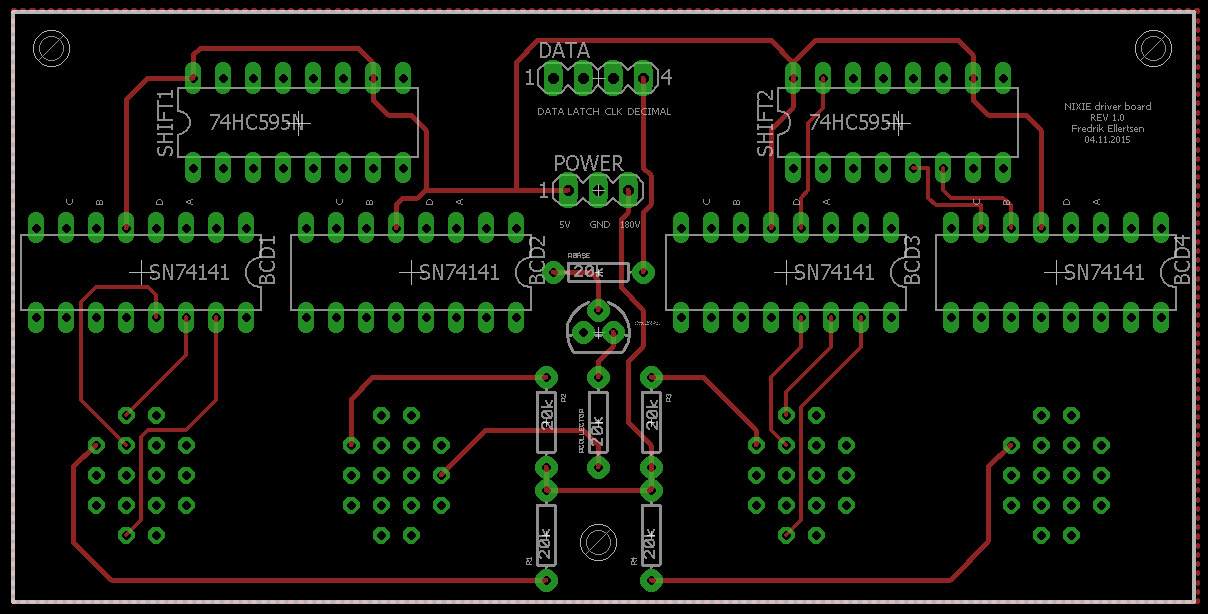

Nixie driver board: shift registers and 180 V DC

A big thanks to

tube-tester.com for providing the ancient

datasheet for these nixie tubes!

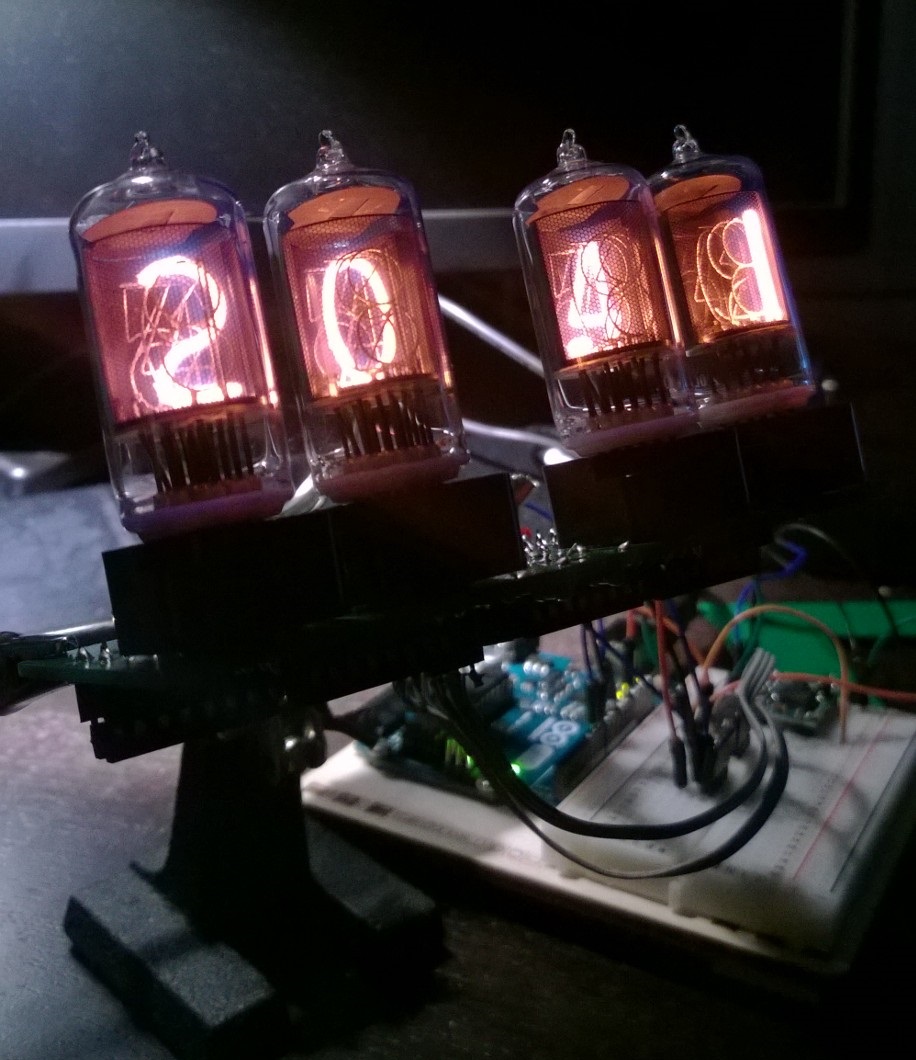

This part of the project that had me worried for a while. The four ZM1000 nixie tubes I salvaged

require

a minimum of 170 V DC supply voltage for ignition and an average anode current of 2.5 mA. Given the

extreme rarity of

this particular nixie tube (and, surprisingly, the even rarer sockets), I was very afraid I might

damage

them by misunderstanding their parameters. Reading the datasheet carefully, I decided to leave the

primer pin floating, and supplying the anodes with 180 V DC through a 20k reistor. The voltage

source

is a cheap 180 V boost converter off eBay, but in hindsight I wish I had built my own, as the one

from eBay

has a terrible coil-whine. Wrapping it in some cloth seems to kill most of the whine until I get

around to

fixing it more permanently.

Now, sinking current at those voltages is not something your ordinary 74-series shift

register can hope handle. Luckily, you can still obtain IC's from the 1970's through eBay which do

just that.

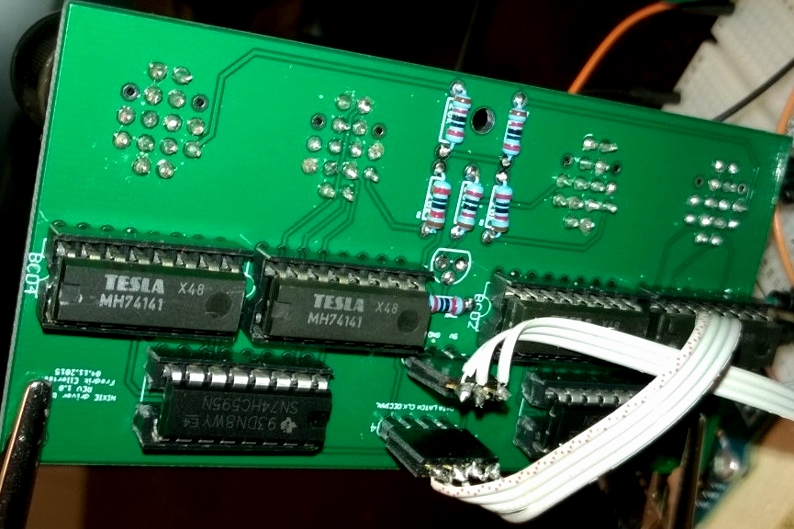

I ordered SN74141-equivalent chips from Ukraine: MilSpec TESLA MH74141, and they work a charm. The

following

is the schematic I ended up with.

The 74141 chips are

BCD, which means

that every nixie tube needs its

own chip. Every chip has four data inputs; A, B, C and D. This adds up nicely so that four digits

can be

controlled with two shift registers. Four bits give 24 = 16 possible values, so binary

inputs of 10-15 are invalid

inputs and will result in all the outputs being high impedance -- perfect for blanking individual

nixies.

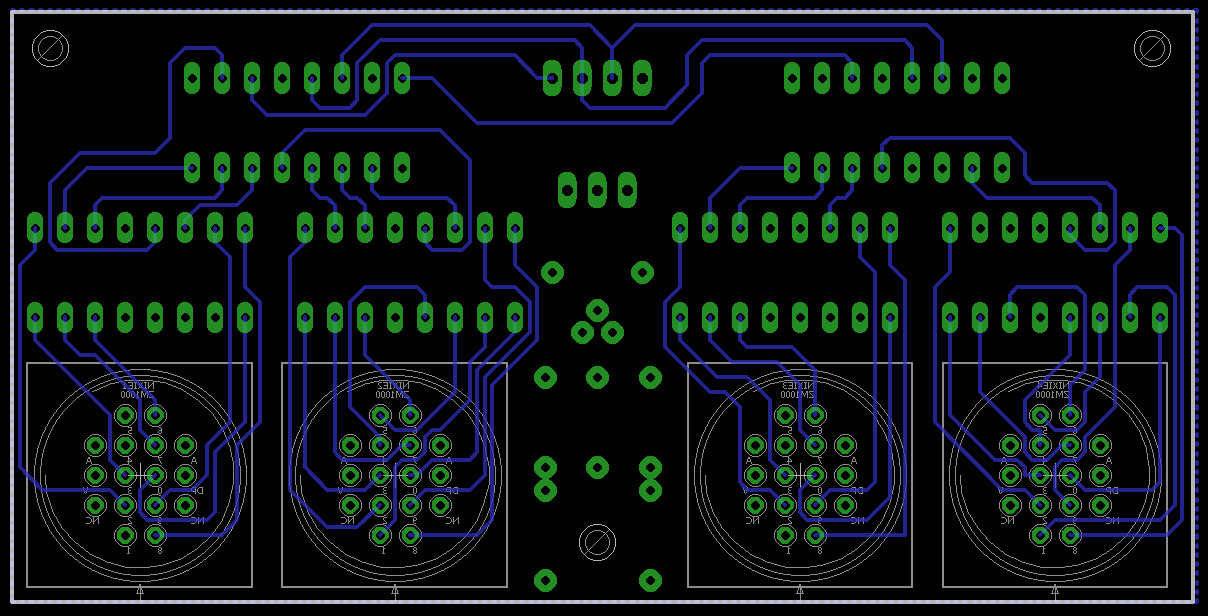

Finding an EAGLE library part for them was impossible, so I designed a package for them.

You can fetch the schematic, board layout and the library part from the bottom of this page. In

order to

pay the respect these beautiful things deserve, I decided to have the circuit board manufactured.

Feeling confident

after successfully designing the display driver board, I set about designing this one too. As with

the rest of the

system, I made sure this board too was modular, with the following header inputs:

180 V,

GND and 5 V plus DATA, LATCH, CLOCK

and

DECIMAL divided over two ribbon cables. The DECIMAL input controls the

gate

of a single high-voltage NPN transistor (MPSA42)

which sinks current from the third nixie's decimal point cathode, thus enabling a blinking decimal.

ZM1000 nixies running at 180 V DC, 2.1 mA with a 20k anode resistor. I won't say more -- just look at the sexy things.

A closer look at the nixie driver. I am using header pins and ribbon cable as connectors -- cheap and easy, though unreliable. These will be sealed with heat shrink tubing later.

Bottom of the circuit board

Top of the circuit board

Miscellaneous pieces of the puzzle: mcu, knobs, power supply etc.

Anticipating the everlasting work-in-progress-nature of this project, I went for perfboard for the

main

circuit board. Connectors are rather expensive, and I didn't bother ordering them

through eBay. Most of the board-to-board connections are therefore done by soldering female headers

to

ribbon cable and mating the header with a male counterpart on the PCB. This isn't the most robust

solution,

but if you make sure the solder joints are good and you add heat shrink tubing to the connectors, it

seems

to work okay for low voltage connections. I did go for proper JST connections on the power

connectors, which also

ensures I don't connect 12 V or 180 V backwards to ground or 5 V. This did happen on one occasion,

which resulted

in a lot of magic smoke and the demise of an ATmega chip and several innocent shift registers.

Luckily no

critical components were damaged.

The timekeeping is done with a breakout board based on the very accurate

DS3231 RTC

module with its own dedicated

button cell battery. The system is powered by 12 V from a (rather large) random power brick I had

laying around.

The heart of the project: Code

Interrupts and timekeeping

At first I wrote all the code in Visual Studio with the Visual Micro

plugin for an Arduino Uno, but I soon switched platforms to the

ATmega644P,

as I was interested in going deeper into microcontroller programming. This part of the project has

definitely been the most time-consuming, mostly due to the fact that I had never programmed anything

AVR,

apart from Arduino. It was a steep learning curve, but I am glad I didn't give up along the way.

The code definitely shows that I am new to this game, but at least it works!

I won't go through every line (if you have any questions or feedback, feel free to

contact me), but I'll explain key features.

Everything in the code is interrupt-driven. On the ATmega644p there are three timers; two 8 bit

timers and one

16 bit timer. The 16 bit timer is used in CTC mode to interrupt every second, calling an ISR every

time the counter reaches

the preset value in the ORC1A register. I derived the following formula from the

datasheet

to calculate the overflow compare value:

where fclk is the system clock frequency (16 MHz),

N is the prescaler value (1024) and fISR is the

interrupt frequency (1 Hz). For these values I get OCR1A = 15625. The theory behind

timer interrupts in AVR has been described exhaustively in numerous tutorials, blogs and posts

around the web, so I will not go into detail about it here.

Display code

In the file display.cpp, you'll see that the class Display has a member

function,

refresh(), which is called every 1/100th second

by another timer interrupt. This function cycles the displayed character as illustrated above. The

function

updateString(char* newStr) generates a string of bytes which is compatible with the

configuration

of shift registers

based on the c-string newStr and a long lookup-table found in header.h.

Nixie digit code

The code which handles the nixie tubes resembles the one controlling the display, but with the added

need for

decimal - BCD conversion. Every 15 seconds the microcontroller fetched the current time from a

DS3231

RTC module.

If one minute has passed, the function Clock::refresh() takes the global variables

seconds,

minutes and hour and generates BCD values for the shift registers. It also

accounts

for whether or not the user wants to print leading zeros and if he/she wants the decimal point to

flash. All this is

done on lines 30 and 31 in Clock::refresh() by the two ugliest lines of code I have

ever written --

but they work. Note to self: don't code after 3 a.m.

Rotary encoder: decoding and debouncing

Quadrature rotary encoders are knobs you can turn infinitely, as opposed to a potentiometer. They

are also digital by

by nature, and are therefore very well suited for simple menu interactions and so on. After studying

Nich

Fugal's very detailed

walk-through on how they work and how you can use them with an Arduino, the setup was easy. The

encoder I use

also incorporates a push-button in the encoder shaft. In encoder.cpp you'll find the

function

Encoder::readEncoderPosition() which is adapted from Nich Fugal's blog post. This

function both

debounces the encoder inputs A and B and calculates the probable direction in which it was turned.

Pulse-width modulation of the LED strip

Timer0 of the ATmega was configured for fast-PWM and toggles PB3 (OC0A) on compare

match with

the OCR0A register. Thus, by changing the value of OCR0A, we change the

duty cycle

of the PWM signal which drives the LED strip. As you might know, humans perceive the world mostly on

a

logarithmic scale, while microcontrollers are most definitely linear in every digital

aspect. To compensate

for this I decided to let the user choose between an exponential and a linear basis for dimming the

light. The function

Light::initializeLists() generates two lists containing respectively linear PWM values

and

exponentially spaced PWM values. Unfortunately, due to the properties of exponentials and the 8 bit

limitation

of OCR0A, the latter list contains a mere 41 steps. This results in a rather jagged

dimming of the light,

but at least it looks linear. I just occurred to me, though, that a sunrise might follow

neither

of these patterns. I promise to look into which patterns produce the best effect and post my

findings.

On a side-note: Inducing lucid dreams!

Having been intrigued by the concept of lucid

dreaming

for a long time, I now finally have equipment which enables me to induce a lucid dreamstate.

Research does back this method of inducing a lucid state. In one study, flashing lights were

administered

through goggles worn by the sleeper, inducing lucidity 33 times over a total of 58 nights with 44

subjects

(LaBerge, Levitan, Rich, & Dement, 1988). Oh yes.

This is not something I have been able to refine yet, though. What separates my crude experiments

from the

study is that they had sensors detecting eye movement through the sleeper's eyelids and activated

the

flashing lights only during REM sleep. I am still only smashing rocks together, but I have

had promising

results. For a couple of weeks I have set the alarm clock to flash the LED strip at around 05.00

a.m.

On at least two occasions the flashing has resulted in terrifying nightmares in which I was sure the

world

was ending and I was going to die (the lights being accompanied by thunderous noises,

interestingly), though

not resulting in a lucid state as far as I can recall. I will play around with the light intensity,

the

flashing frequency and the time interval during which the lights flash and post my findings.

Update: I am designing a wearable system which, using electrooculography, will be able to

detect REM

sleep. Through the use of light stimuli provided by the wearable, I will hopefully be able to induce

lucid

dreams. Click here to read more!

Physical assembly: Oak, plexiglass and excellent light diffusion

At this point I'm several months into the project and I am very anxious to collect everything and

install it

in a permanent box. Having dry-fitted the system in a suitable cardboard box for longer than I care

to admit,

I went down to my local hardware store and purchased a length of solid oak shelving

(15 by 3 cm), an acrylic sheet, decorative molding, some tools, miscellaneous screws, angle brackets

and so on.

Loosely following the dimensions of the cardboard box I constructed a basic shape. The top plate is

screwed in from

the sides, and the plexiglass front can slide out.

I drilled undersized holes in the back plate and hammered in PCB spacers in order to fasten the

three circuit boards,

which is surprisingly sturdy. The arm switch and the rotary encoder are fastened with nuts through

the plexiglass.

Fastening the LED strips to an angled wooden molding which spans the entire width of the box

I keep the inside of the box shielded from the light as well as directing the light outwards. Using

very fine

sandpaper I diffused the bottom of the plexiglass in order to hide the LED strip as well as

spreading the light.

This worked really well; It hides the fact that the light consists of several small LED

modules without

compromising brightness or light quality. It is, however, important to polish vertically, not

horizontally.

If the minute grooves in the acrylic material from the sanding are parallel to the LED strip, the

resulting

effect will not be diffusion -- rather, you will reinforce the feeling of the light being

"one-dimensional".

Having designed this system without the assembly in mind, everything was a mess of ribbon cables.

The highly modular

nature of the system is one of the reasons why the box is so large. In order to clean up the mess of

cables

I stripped some thick copper wire and shaped it into a hook. The shape became

quite rigid after applying loads of solder. Fastening it to the bottom plate of the box I was able

to

secure the display right behind the plexiglass as you can see in the image to the right. Not only

does this

look cool, but it allows much more insight behind the display than what you would have if the

display was

fastened to a large PCB. I made another hook for cable management inside the box.

Final polishing was done with coarse sand paper and extra virgin olive oil. I hope my clock won't go

rancid

on me.

Dryfitting the system in a cardboard box.

A look through the transparent front. You can see the how the plexiglass is polished: Vertically, not horizontally

Links and downloads

-

Full source code: download .rar

-

Board schematic EAGLE files: download .rar